Choosing the right chemical protective clothing can be challenging, as no one type of clothing can protect against all levels of chemicals. There are many factors to consider, including the types of barriers, exposure scenarios, and duration of exposure. To assist the frontline worker in making the right selection, it is important to follow a standard.

Since the first standard for chemical protective clothing emerged mid to late 1980’s, different regions and countries have developed standards over time that carefully defined the requirements for garment performance, product testing methods, and technical documents. There are three common standards for chemical protective clothing: ISO standard, European Regulation, and US legislation.

ISO Standard

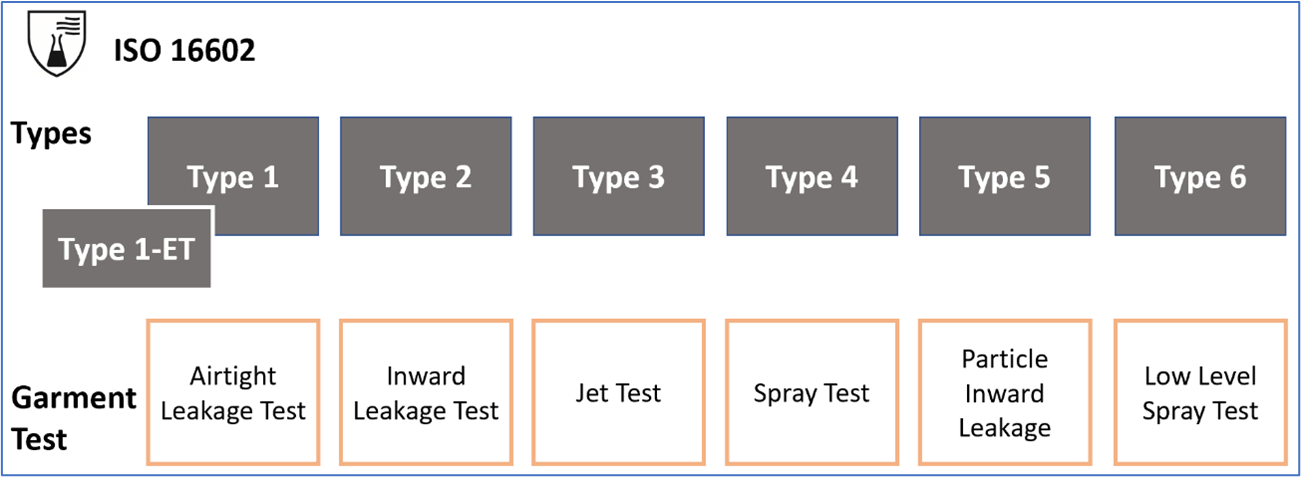

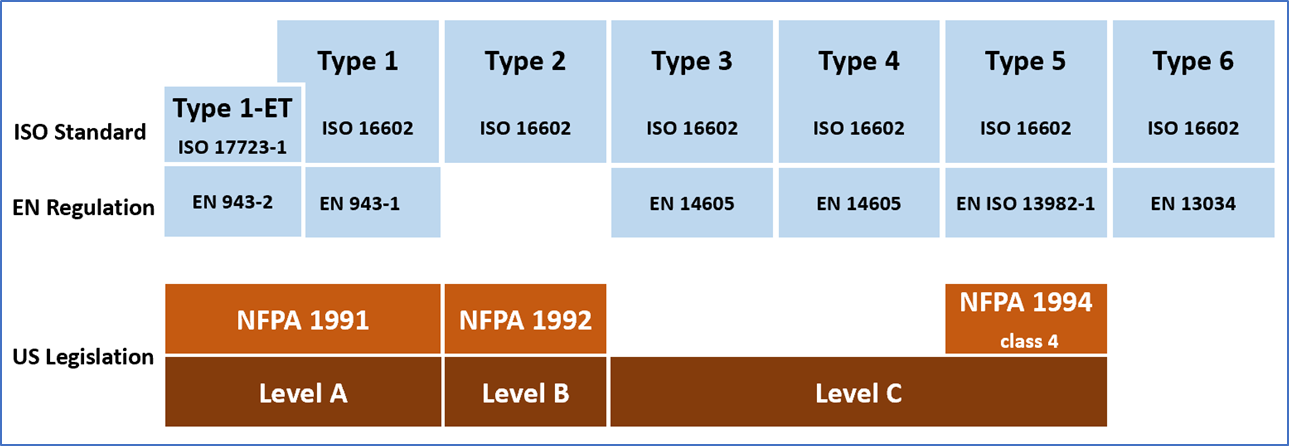

Under the ISO standard, the common reference for chemical protective clothing is ISO 16602. This standard categorizes chemical protective clothing into six basic types, based on whole garment testing: Type 1 is Airtight Leakage Test, Type 2 is Inward Leakage Test, Type 3 is Jet Test, Type 4 is Spray Test, Type 5 is Particle Inward Leakage Test, Type 6 is Low Level Spray Test. And a side category from Type 1 is Type 1-ET by EN 17702-1 ensembles for emergency response teams.

In addition to garment testing, the ISO standard also specifies performance requirements and testing methods of materials in physical properties and chemical resistance for each clothing type.

Pic 1: Types and Garment Test in ISO 16602

European Regulation

Unlike the ISO 16602 standard, which includes all definitions and requirements for chemical protective clothing in one document, the European regulation has multiple standards for each performance requirement and testing method. Chemical protective clothing is classified as a “Category III” PPE product under Regulation (EU)2016/425 against high-level risk, and each type of garment is recognized by individual standards. However, the European regulation does not include a Type 2 classification, as it was canceled. The rest types of garments need to pass the specific criteria of each test method, also the materials and assemblies used in the chemical protective clothing must meet the requirements in EN 14325.

| Type 1 | Type 3 | Type 4 | Type 5 | Type 6 | |

| Garment Standard | EN 943-1/2 | EN 14605 | EN 14605 | EN ISO 13982-1 | EN 13034 |

| Garment Test Method | EN 943-1/2 | EN ISO 17491-3 | EN ISO 17491-4 | EN ISO 13982-2 | EN ISO 17491-4 |

| Materials Requirement | EN 14325 (Include test methods and performance classification for materials) | ||||

Table 1: EN Standards for Garment and Materials Requirement

Despite some differences in the specific standards and requirements, the performance expectations for chemical protective clothing in Europe regulations are similar to those outlined in ISO standard. Both the European regulations and ISO 16602 standard classify garments based on whole garment testing, and both have similar test methods for material requirements in both physical and chemical properties. Please refer to below table to find the test requirements of EN 14325 and ISO 16602.

| Type 1 | Type 2* | Type 3 | Type 4 | Type 5 | Type 6 | |

| Chemical Permeation | Ο | Ο | Ο | Ο | ||

| Test Method: ISO 6529 | ||||||

| Chemical Penetration / Repellency | Ο | |||||

| Test Method: ISO 6530 | ||||||

| Abrasion Resistance | Ο | Ο | Ο | Ο | Ο | Ο |

| Test Method: ISO 12943-2 (EN 530) | ||||||

| Flex Cracking resistance | Ο | Ο | Ο | Ο | Ο | |

| Test Method: ISO 7854 | ||||||

| Tear Strength | Ο | Ο | Ο | Ο | Ο | Ο |

| Test Method: ISO 9073-4 | ||||||

| Tensile Strength | Ο | Ο | Ο | Ο | Ο | |

| Test Method: ISO 13934-1 | ||||||

| Puncture Resistance | Ο | Ο | Ο | Ο | Ο | Ο |

| Test Method: ISO 13996 (EN 863) | ||||||

| Seam Strength | Ο | Ο | Ο | Ο | Ο | Ο |

| Test Method: ISO 13935-2 | ||||||

| Ignition Test | Ο | Ο | Ο | Ο | ||

| Test Method: ISO 13274-4 | ||||||

| * Note: Type 2 was canceled in Europe Regulation | ||||||

Table 2: Test Item for Type 1 to Type 6 Garment According to EN 14325 and ISO 16602

US Legislation

The US government has a regulation “29 CFR 1910.32” that requires employers to determine the appropriate PPE needed to protect against hazards in the workplace. However, the regulation does not specify how to determine what is appropriate or the required performance standards. Instead, the OSHA and EPA provide a guideline on four levels of hazardous work environments, ranging from high to low risk, that requires skin and respiratory protection. These levels are categorized as Level A to D, and the related PPE are summarized in the table below.

| Level | PPE Requirement | Respirator | Clothing |

| A | Protection is required when the greatest potential for exposure to hazards and the highest level of PPE. | Positive-pressure, full-face piece SCBA or air supplied respirator | Encapsulation vapor tight and chemical protective suit |

| B | Protection is required under circumstances requiring the highest level of respiratory protection, with a lesser level of skin protection. | Hooded and non-airtight chemical resistant clothing | |

| C | Protection is required when the concentration and type of airborne substances is known and the criteria for using air purifying respirators is met. | Full / half face mask, or (powered) air purifying respirator | |

| D | Protection is the minimum protection required. | Optional | Water repellent gowns or scrub |

Table 3: Respirator and Clothing Selection under OSHA/EPA Levels of Hazardous Environment

There are also several NFPA standards used by some manufacturers to claim the performance of chemical protective clothing. These standards are primarily designed for firefighters, emergency responders, and hazmat teams, but they can also be applied in industrial to protect against hazards.

NFPA 1991 “Standard on Vapor-Protective Ensembles for Hazardous Materials Emergencies and CBRN Terrorism Incidents” meets the requirement of clothing design in Level A. It’s similar to EN 943-2 for Emergency Response purpose but also specify the testing against flash-fire escape ability.

NFPA 1992 “Standard on Liquid Splash-Protective Ensembles and Clothing for Hazardous Materials Emergencies” meets the requirements of clothing design in Level B. It’s similar to ISO 16602 Type 2 but no permeation test was performed. It also specifies the testing against flash-fire escape ability.

NFPA 1994 “Standard on Protective Ensembles for First Responders to CBRN Terrorism Incidents” have several classes and the class 4 provides particulate protection assessed using a whole garment particulate inward leakage test. But also require the comfort and biological protection.

Overview

These three common standards set the minimum requirements for different risk at work environments. In the following we will talk about the ISO, EN and US standards that are related to chemical protective clothing, to realign the vapor protection, liquid protection and particulate protection garment, and a better explanation of the protection levels.

Pic 2: The Standards from ISO, EN and US for Chemical Protective Clothing

There are also many standards among global countries for chemical protective clothing, but can’t all be listed here. Such as Brazil offered the Certificate of Approval (CA) issued by an official national body. Japan has its own standard JIST 8115 which is equivalent to ISO 16602 and EN regulations. Korea has the KOSHA certification to ensure frontline workers use the correct PPE for work. Taiwan has the CNS standard to align with global regulation. Back to basics, only the EU Regulation system is most used and has a certified process by a third party. The standards of countries just mentioned are applied or similar to ISO 16602 and EU Regulations for garment type classification and performance requirements.

No matter which standards are referred to, the goal of these standards is to provide objective information to help frontline workers in safety and occupational health choose appropriate chemical protective clothing against hazards. The importance of chemical protective clothing is paramount, as it provides the last line of defense against injury.