Coverall Selection Guide: Key Considerations of Users

The COVID-19 pandemic brought a great impact on increasing the production of protective equipment to cope with the rising demand, panic buying, hoarding and misuse of these protective gadgets. Since these are mainly for frontline operators to combat the coronavirus, there is a rise in stringent government regulations towards Personal Protective Equipment (PPE) as life matters most.

From the past articles, we have been educating about the difference between gown and coverall, EN 14126 against infective agents, and The Golden Triangle Rules to go home safely. We shall now focus on the coverall construction details namely Garment Design, Fabric Technology and Seam Technology, as they are the key considerations related to comfort and functionality for working efficiency.

Garment Design of Coverall

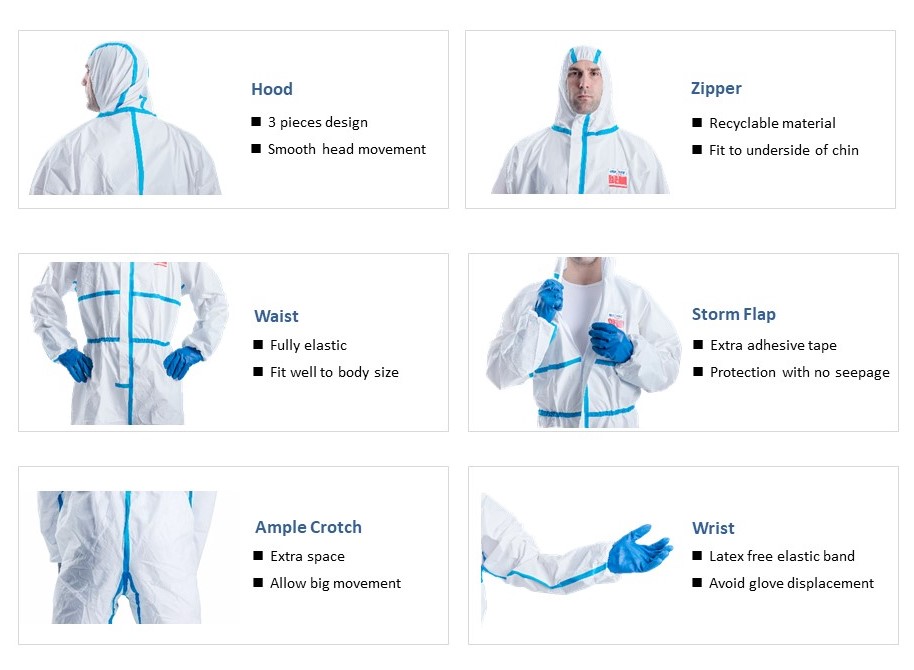

The garment design can be considered as part of the coverall selection process, especially when certain features including closures will greatly affect protection. For example, a coverall with a front zipper closure could result in the compromise of barrier protection if the zipper used is not covered with a storm flap or adhesive tape that can be further sealed to the garment. This is especially important when biological hazards or contaminated fluids may come from many directions without notice. If your working mode requires major movement like squatting and crawling, you will need ample space through the crotch to prevent the rupture of the fabric.

Besides the front zipper and storm flap, 3-piece hoods are applied to the coverall for optimal head fit and smooth head movement. The 3-piece hoods have three pieces of fabric sewn together with two seams. The seams run from the back of the neck all the way to the front of the hood and are located on either side of what would be a centerline. The extra fabric piece and seam make the hood more form-fitting, comfortable and helps it stay in place better than the 2-piece design.

Figure 1. Ergonomic design applied for coverall

Fabric Technology of Coverall

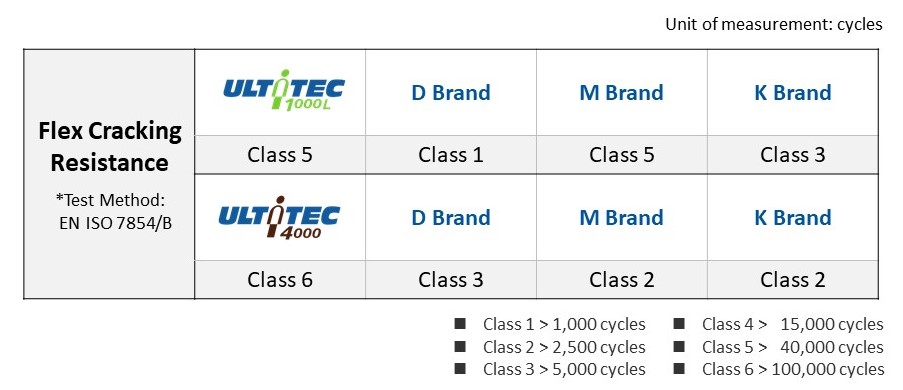

An unprecedented rise in the COVID-19 pandemic has put the lives of frontline operators at high risk. These frontline heroes are suffering due to large-scale unavailability of PPE, majorly coveralls, or even if they have it, it is not made according to standards. According to our industry experience of nearly 30 years, we encourage users to pay attention to fabric physical properties, namely abrasion resistance, flex cracking resistance, trapezoidal tear resistance, tensile strength, puncture resistance, etc.

These fabric physical performances can be a reference point during the selection of appropriate protective clothing for your workplace. For example, flex cracking resistance is important for industrial applications, as the daily tasks can be very physical and need hard-wearing coveralls. Thus, the flexibility of the fabric should become a key consideration for users. Their work situations will need to wear coveralls for long hours and the fabric will be flexed and creased through the day in conjunction with their working movements. Therefore, it is necessary to have a coverall made from fabric that is not likely to crack and thus provide a weak point for penetration of potentially harmful particulates or liquids.

Chart 1. Flex cracking resistance comparison among key market players

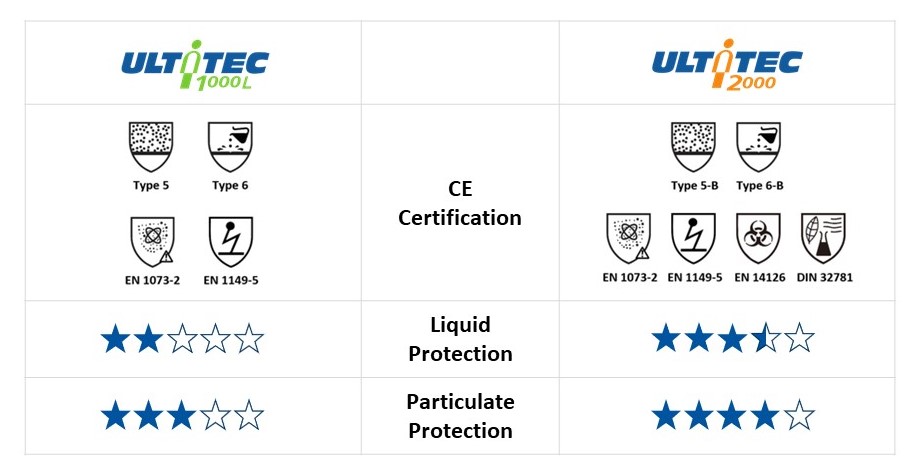

During this pandemic, besides educating on fabric physical performances, we have been communicating to users that instead of fabric weight, users should concern more about the protection capabilities. Because we have a full series of coveralls, and they might look the same at the first glance, knowing more about the differentiation becomes especially important to get appropriate protection against your potential hazards in the workplace. Even though they might be classified as the same Type certification, their protection level might differ when running into the same hazards.

Chart 2. Comparison of coveralls based on protection level

If there are two coveralls with similar Type 5 certification, when particulate protection is needed, ULTITEC 1000L is sufficient. But if liquid protection is needed, ULITEC 2000 is a more appropriate option. If the liquid involves pesticides, a coverall with DIN 32781 certification is required during the pesticide spraying process. Moreover, if your workplace may encounter biological hazards, CE certification of EN 14126 against infective agents will become a key factor in coverall selection.

Seam Technology of Coverall

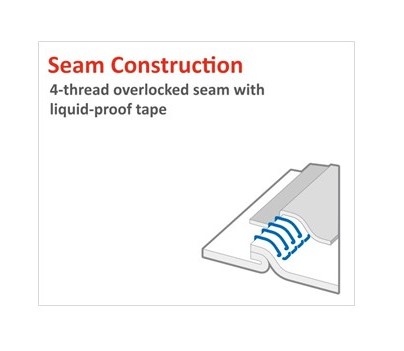

Besides garment design and fabric construction, seam construction is relatively important before a coverall can be classified as appropriate protective clothing. There are multiple seam methods available in the market, mainly consists of the overlocked seam (either 3 or 4 threads), stitched with tape seam, ultrasonic seam, bound stitched seam and others.

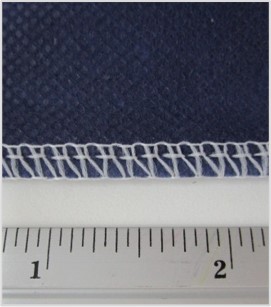

Figure 2. Stronger 4-thread overlocked seam

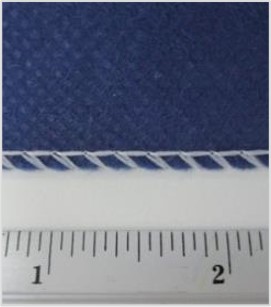

Figure 3. Normal 3-thread seam

Among all seams, instead of 3 threads which are commonly used by market players, a deeper 4-thread overlocked seam is the simplest yet effective in holding the fabric together and protecting against liquid splashes as well as dry particulates. If a higher level of leak resistance is needed, liquid-proof tapes can be applied over the seam to ensure users being protected with no seepage. The seam construction should be appropriate for the level of protection needed.

Figure 4. Overlocked seam with liquid-proof tape

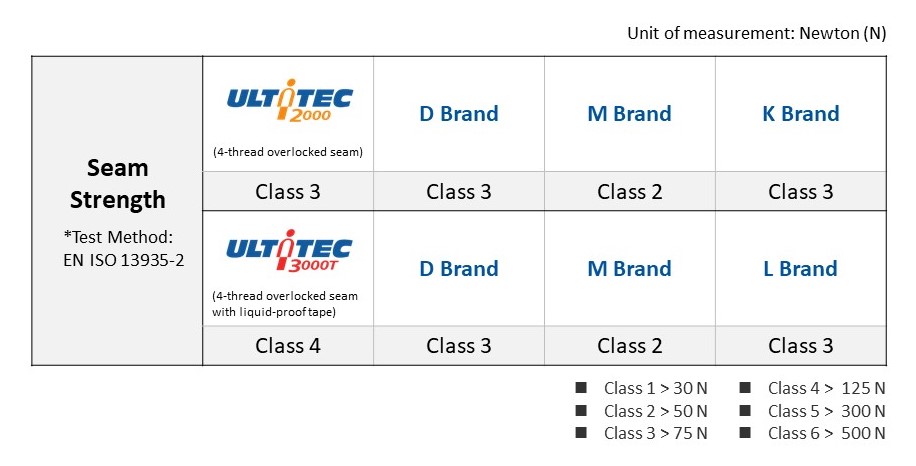

Chart 3. Seam strength comparison among key market players

Different seam types will then result in different seam strengths, it can then affect the quality and appearance of coveralls. Moreover, the performance of the seams is dependent upon the stitch density, stitch width, seam allowance, stitch length, seam thickness, sewing needle penetration force and others. Seams of the coverall must be durable and smooth, or else it will result in negative extensibility, durability and efficiency of the seams.

Conclusion

Good coveralls offer more than protection but include in comfort and functionality for working efficiency. Besides abiding by the world-recognized PPE Regulation (EU) 2016/425, the Garment Design, Fabric Technology and Seam Technology are three key considerations for users in their coverall selection process. These product information can be requested from the manufacturer and they shall provide users with Technical Data Sheet (TDS) to allow a deep understanding of the coveralls prior to purchase action. Make sure you choose coveralls that not only offer the protection you need but ones that will make life at your job better!