Premium Oil, Liquid Splash & Biohazards Resistant Protective Clothing

Designed to protect wearers against heavy liquid splash and biological hazards. Widely applied by worldwide government organization in disease control.

- TYPE 5 EN ISO 13982-1 Dry Particle Suits-Suits for protection against hazardous dust and any dry particles.

- TYPE 6 EN 13034 Reduced Spray Suits- Determination of resistance to penetration by reduced liquid spray.

- EN 1149-5 Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5×10 exp 9 ohms.

- EN 1073-2 Protective clothing against particulate radioactive contamination.

- EN 14126 Protective clothing can resist against biological hazards and infective agents.

Features

- Outstanding barrier against oil and heavy liquid splash, reaches the highest standard of biohazard protection.

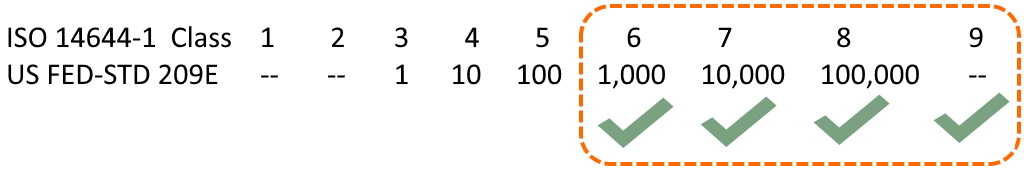

- Suitable for cleanroom environment with controlled variables. Meets the standard of ISO Class 6 and above.

Note*: The WHO recommended specification for coveralls against filovirus disease issued in Oct, 2014 stated that healthcare workers should choose appropriate protective apparel, which meets the following two requirements:

option 1, tested for resistance to blood and body fluid penetration: meets or exceeds ISO 16603 class 3 exposure pressure.

option 2, tested for resistance to blood-borne pathogen penetration; meets or exceeds ISO 16604 class 2 exposure pressure.

Note**: ULTITEC 2000 coverall is suitable for both ISO 14644-1 and US FED-STD 209E cleanroom standard. Test result shown in the following table:

Applications

Agriculture, Automotive, Biological Hazards, Disaster Management, Disease Control, Pharmaceutical

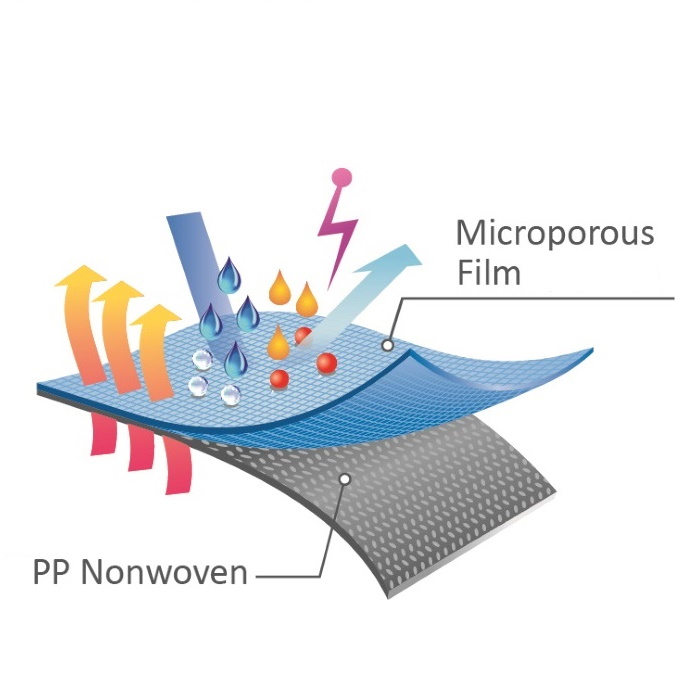

Fabric

Microporous Film Laminated PPSB

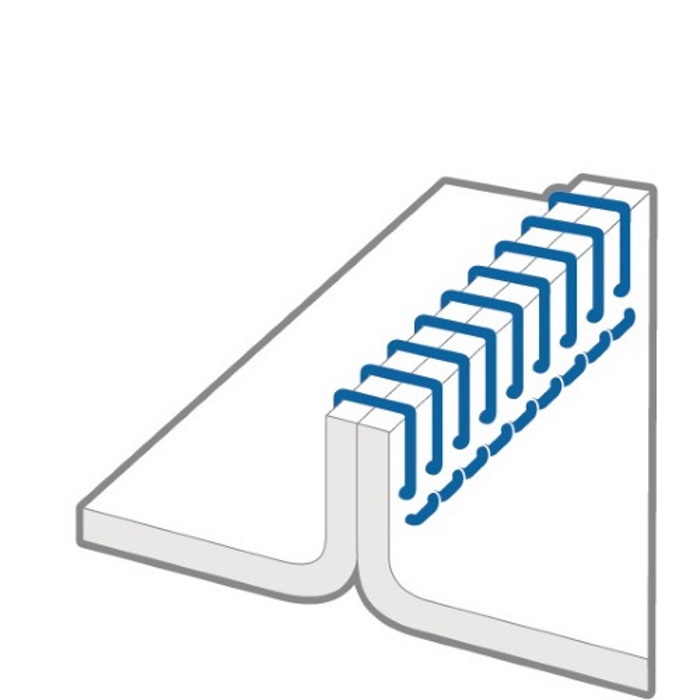

Seam

- 4-thread overlocked seam

- 7-9 stitches per inch

- Thread fibre is 150D

- Bite depth at 4mm